Abrasives: Cutting Wheels and Grinding Wheels

Like other tool accessories, abrasive wheels have their own terminology and design features. This article explains the basics about grinding wheel abrasives.

The power tool industry uses a specialized system of terms to organize and name abrasive grinding wheels and cutting wheels.

Like most other power tool accessories, abrasive wheels are available in a huge variety of types and styles suited for different applications, and most of these types and styles are separated by only small variations in materials and design features.

Cutting wheels and grinding wheels are custom fit to their jobs by a combination of a wheel's measurements, abrasive material, grit, hardness, bond material, and wheel type.

Each of these abrasive wheel design features are explained below, giving shoppers the information they need to quickly match compatible abrasive wheelsto their tools and applications.

Abrasive Wheel Measurements

It's important to consider a few measurements and specifications when shopping for abrasive wheels.

The items listed below help shoppers match a wheel to its tool, and they also provide some guidelines for use:

Diameter-

This measurement partially determines wheel-to-tool compatibility. For cupped wheels, the largest diameter on the wheel is measured.

Arbor size-

Also used for matching tool compatibility.

Thickness-

Contributes to matching tool compatibility and application. Cutting wheels, for example, are thinner than grinding wheels.

Max RPMs-

Not a measurement, but a specification. A number of production factors determine each abrasive wheel's "radial tensile strength" (the rotational speed at which centrifugal forces will tear the wheel apart).

The max RPM specification tells users the maximum speed at which it is safe to operate each unique wheel.

Color Coded Application System

Most manufacturers follow an industry color code labeling system that marks the intended application material for each abrasive wheel.

Abrasive Wheel Color Code System

This color code is usually located on the wheel label where the ANSI marking system name is printed.

Sometimes the entire box that contains the ANSI name is shaded to the corresponding application color, and sometimes only the text of the ANSI name matches the corresponding color.

ANSI Standard Marking System

The power tool industry also uses the ANSI (American National Standards Institute) marking system to identify material types and material specifications used in the production of abrasive wheels.

The ANSI marking system is a shorthand naming system that communicates a lot of information about abrasive wheels in a very short space.

The naming system includes information regarding four things:

1. what kind of grain material an abrasive wheel uses, 2. the grit (or size) of the abrasive particles in the wheel, 3. the overall hardness of the wheel, and 4. the type of bonding material used.

This is the syntax for the ANSI marking system:

[Grain Material][Grit][Hardness]-[Bond Material]

Example: "C24S-BF" is an ANSI marking system name for a common type of masonry grinding wheel.

- "C" here refers to the wheel's grain material (Silicon Carbide in this case).

- "24" is the grit of the wheel (on the coarse side).

- "S" is the hardness of the wheel (on the harder side of the scale), and

- "BR" is the bonding material used in the wheel (Resinoid Reinforced in this case).

- [C][24][S]-[BF]

We explain each part of the ANSI marking system below in more detail.

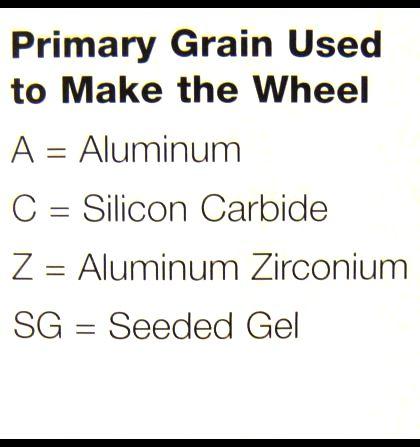

Grain Material

The first portion of an abrasive wheel's ANSI name is one or two letters that indicate(s) the type of abrasive grain material used in the wheel.

Abrasive Grain Material Shorthand

The properties of different abrasive wheel grain materials make them better for different applications and application materials.

Abrasive wheels for power tools are typically made from one of the types of abrasive materials listed below:

Aluminum Oxide-

Aluminum oxide grains are coarse and blocky. Aluminum oxide abrasive wheels are tough, widely used, and promote long life for the wheel.

These are best suited for metal cutting and grinding, including ferrous metals.

ANSI notation: "A"

Silicon Carbide-

With a sharper grain shape, silicon carbide is a great abrasive for concrete and masonry applications. It is a hard abrasive, but more brittle than aluminum oxide.

Silicon carbide is also used for non-ferrous metal grinding, like aluminum metal work.

ANSI notation: "C"

Aluminum Zirconium-

Aluminum zirconium is a very fine, dense grain abrasive, and is the toughest abrasive derived from aluminum.

These wheels are used for very rapid, aggressive stock removal and are very durable.

ANSI notation: "Z" and sometimes "ZA"

Seeded Gel-

These high performance wheels are made by a carefully controlled manufacturing process using aluminum oxide grains. The grains are powdered very small and slowly fused with a bonding agent.

Seeded gel abrasive wheels last the longest of those described here, they stay sharp the longest, and they require the least maintenance.

ANSI notation: "SG"

Grit

Grit simply refers to the size of the abrasive grains infused in a wheel. Varying grit sizes give abrasive wheels varying degrees of aggression and durability.

Instead of using the actual measurements of the abrasive grains, the tool industry uses rounder figures for measuring grit from what is called the CAMI scale. (Conversion charts can easily be found between CAMI units and particle size if needed)

The chart below provides a general idea of grit ranges for abrasive cutting wheels and grinding wheels:

Abrasive Wheel Grit Chart

The grit number occupies the second portion of a wheel's ANSI name.

Hardness

The hardness of an abrasive wheel partially determines how quickly the wheel will wear against different materials, and how aggressively the wheel will clear material.

Because of this, hardness also helps to determine a wheel's optimal application materials.

The tool industry uses the ANSI hardness scale that progresses from softer to harder from A to Z.

Abrasive Wheel Hardness Scale

This letter is the third portion of a wheel's ANSI name.

Bond Material

The abrasive grains in cutting and grinding wheels have to be held together by some kind of material, a bonding material.

There are several varieties of bonding materials and bonding methods, including fiberglass mesh reinforcement.

One or two letters make up the last portion of a wheel's ANSI name after the dash, indicating the bonding material used in that wheel.

Abrasive Wheel Bond Material Shorthand

Cutting and Grinding Wheel Types

Lastly, the shape and thickness of a grinding wheel decide a wheel's type. Abrasive wheel types use a type numbering system.

We explain the features and applications of the most common types of abrasive wheels below:

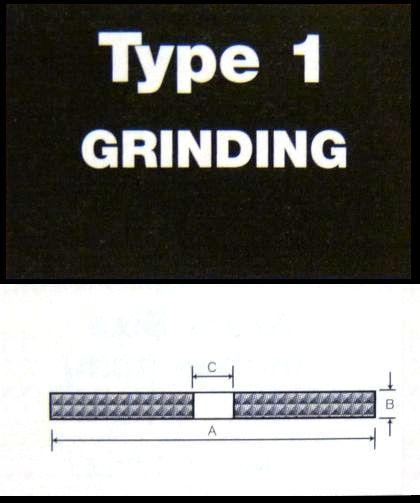

Type 1 Straight Grinding Wheel

An all around edge grinding wheel design. Not used for cutting.

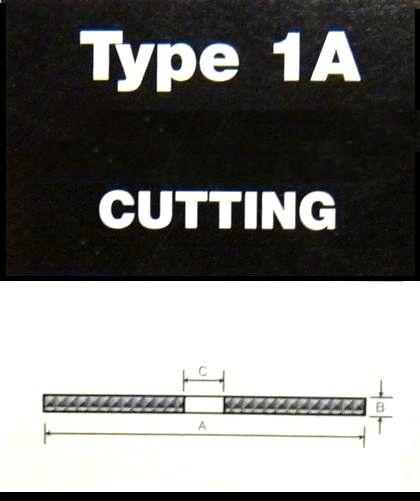

Type 1A Straight Cutting Wheel

A thinner variation of Type 1 grinding wheels. Type 1A wheels are used for 90 degree angle cutting.

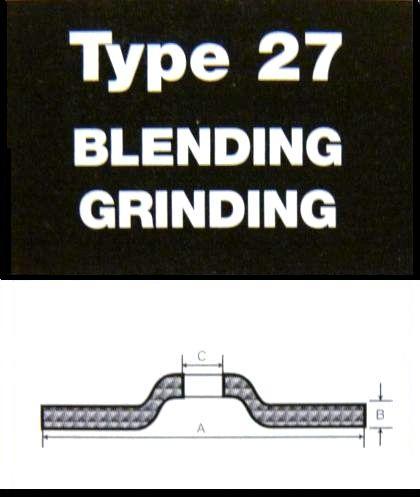

Type 27 Depressed Center Grinding Wheel

Grinding wheels with depressed centers, like Type 27 wheels, are used for grinding on flat surfaces and edge cleaning.

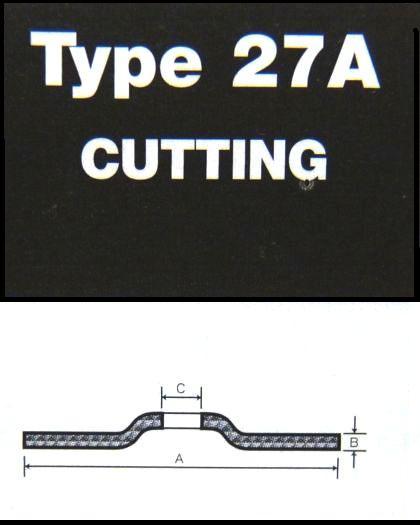

Type 27A Depressed Center Cutting Wheel

Type 27A cutting wheels are best for light cut-off work, as they are a thinner version of Type 27 wheels.

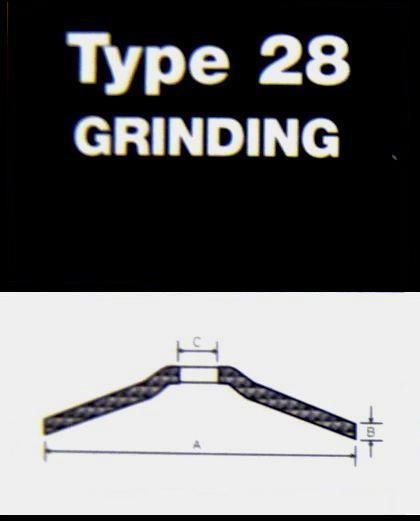

Type 28 Saucer Grinding Wheel

This design offers great area coverage and improved user visibility for de-burring work and other edge preparation work.

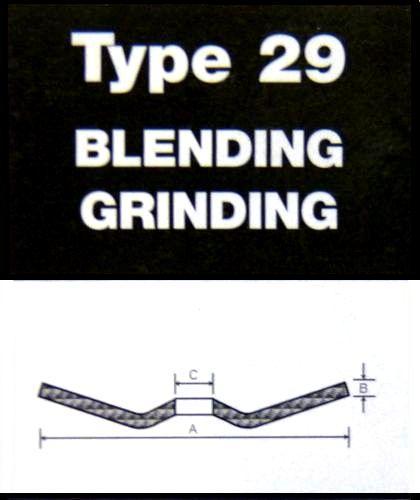

Type 29 Flexible Grinding Wheel

A flexible design makes these abrasive wheels capable of smoothing and grinding contoured surfaces.

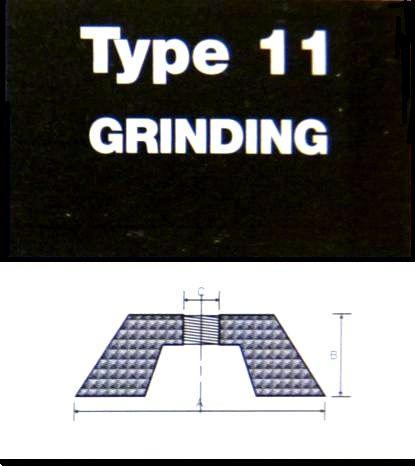

Type 11 Flared Cup Grinding Wheel

Abrasive cup wheels offer even more area coverage than saucer shaped wheels.

These are best for clearing material on large flat areas.